Wear resistant round link chains

Wear resistant round link chains: hardened technical UT chains, hardened special US chains, case hardened technical NT chains and case hardened special NS chains.

Characteristics

- geometry consistent with DIN 22252 standard

- higher wear resistance

- higher mechanical properties

- variable hardness in one link for FAS US-EXTRA (grade 11)

- optimal for stone transport

Application

- flight bar conveyors

- roadheaders

- bucket elevators

- pipe conveyors

Industry branches

- mining industry

- power industry

- sugar industry

- agriculture

- food industry

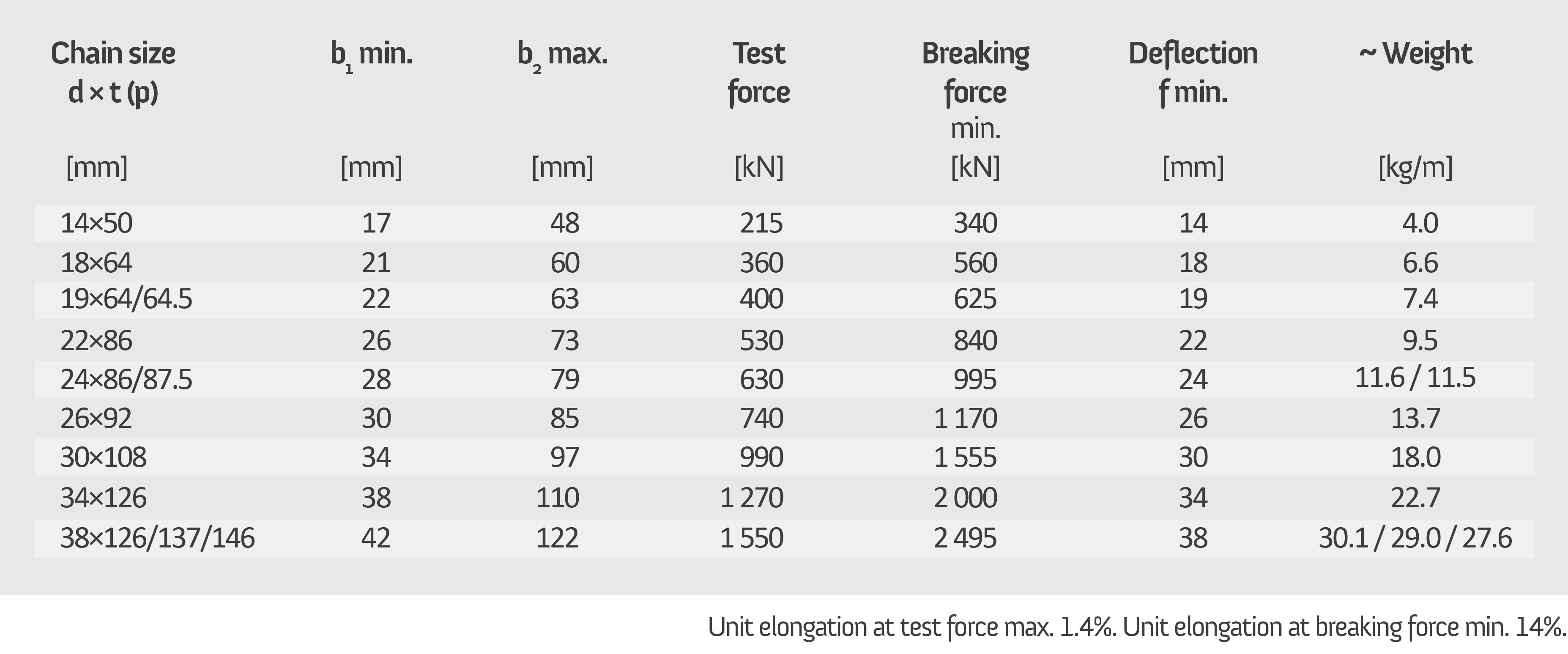

FAS-US

Wear resistant round link chains.

Hardened, special.

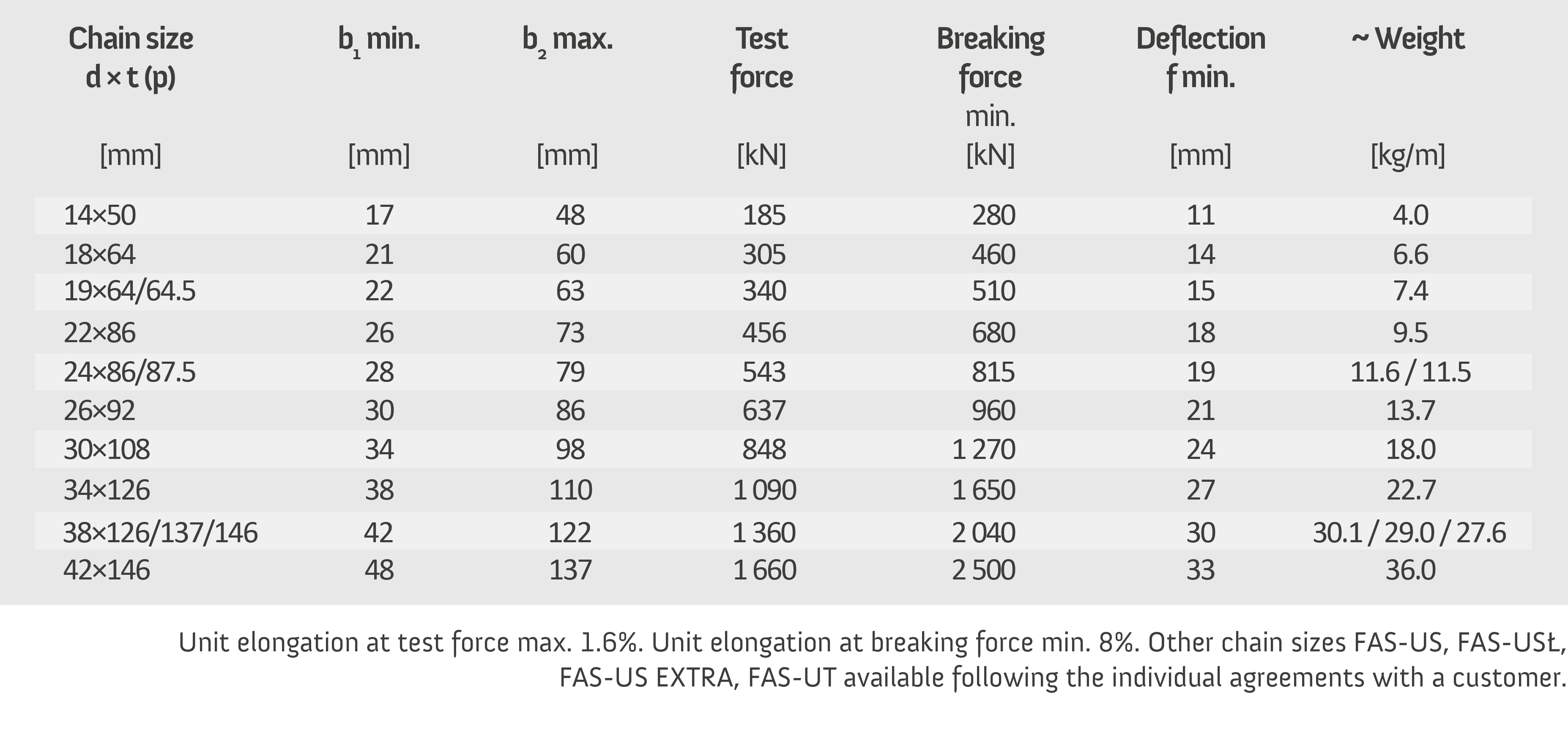

Dimensions and mechanical properties

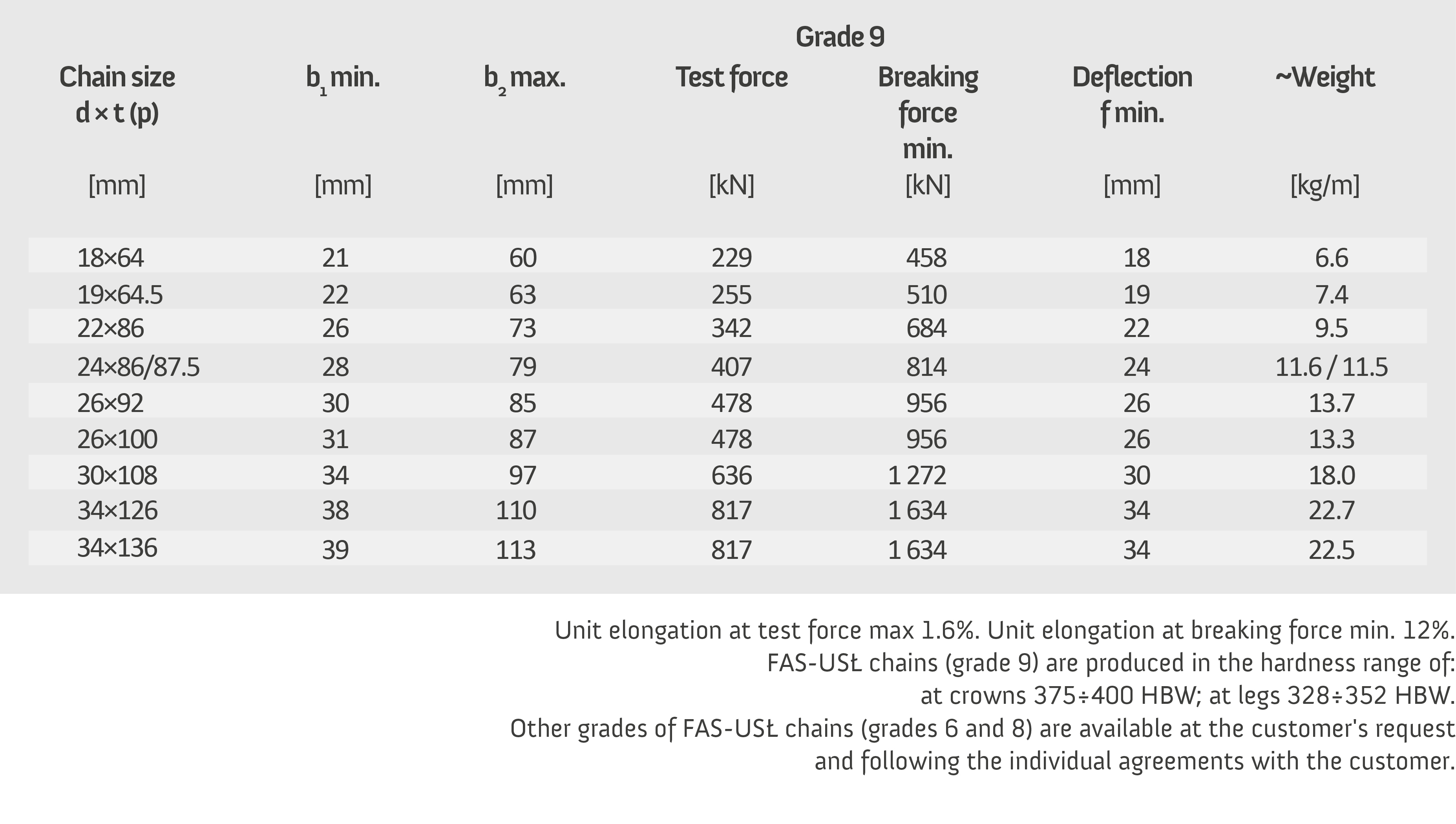

FAS-USŁ

Wear resistant round link chains.

Crown hardened, special - annealed.

Dimensions and mechanical properties

FAS-US EXTRA

Wear resistant round link chains.

Hardened, special.

Characteristics

Round link chains of increased strength and highest wear resistance, particularly at link crowns. The chains are to be used, according to specialist expertise, in the performance conditions where the standard chains of grade C, acc. to DIN 22252 and/or PN-G-46701, have decreased durability as a result of: fast surface wear in operating chain link crowns, fast increase in deflection value and the need of chain replacement because of non- cooperation with sprockets. It is advised to use FAS-US EXTRA chains with FASING flight bars of appropriate design and parameters (complete chain assembly). FAS-US EXTRA chains are manufactured according to the technical and production process, DIN 22252 and/or PN-G-46701 standards and FASING Technical Requirements.

Application

FAS-US EXTRA chains of grade 11 ≥1100MPa are used in mining chain conveyors, AFCs and other types of conveyors, gangway loaders in road header machines; and in the environment with stone presence.

Operation durability of FAS-US EXTRA chains under the following conditions i.e. proper wear degree, fitting flight bar and sprocket design, proper control of initial chain tension, are two, three and more times longer in comparison to the standard chains of grade C, acc. to DIN 22252 and/or PN-G-46701, moreover, they are 20-25% longer than the ones of FAS-US chains.

Dimensions and mechanical properties

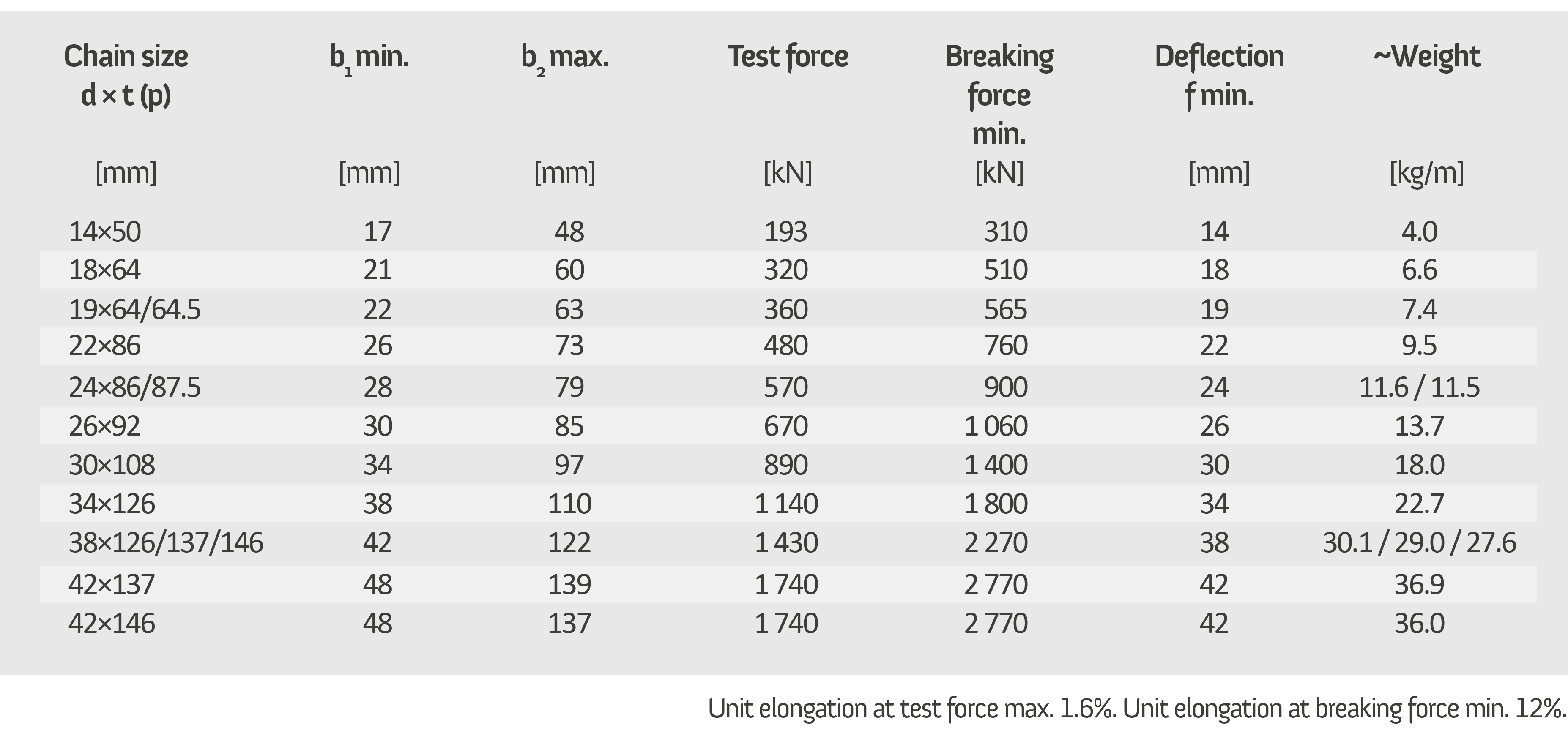

FAS-UT

Wear resistant round link chains.

Hardened, technical.

Dimensions and mechanical properties

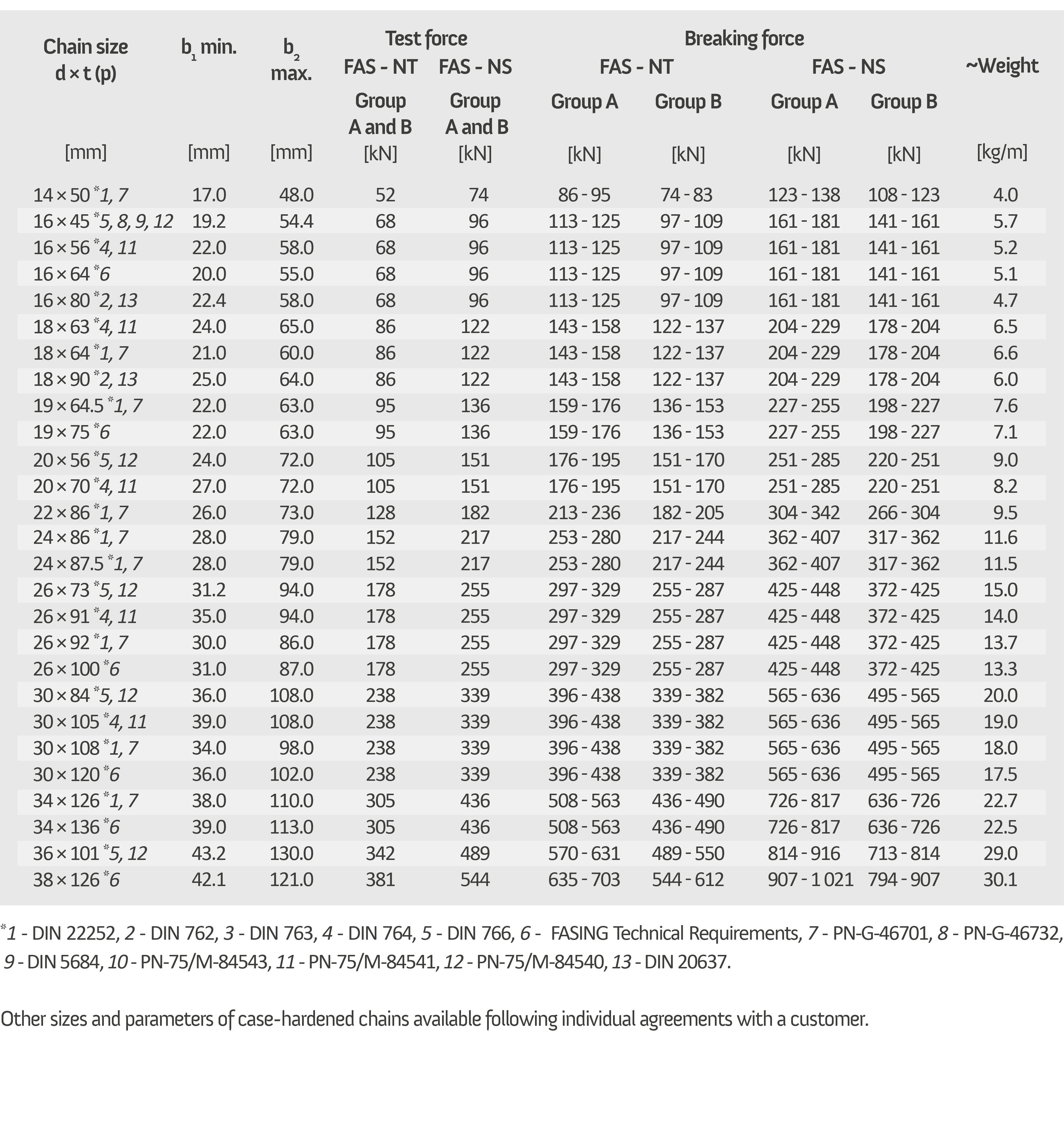

FAS-NT

Wear resistant round link chains.

Case hardened, technical.

Application

Used in equipment for which high wear resistance in chains is required.

FAS-NS

Wear resistant round link chains.

Case hardened, special.

Application

Used in conditions for which both high wear resistance

and relatively high strength properties are required.

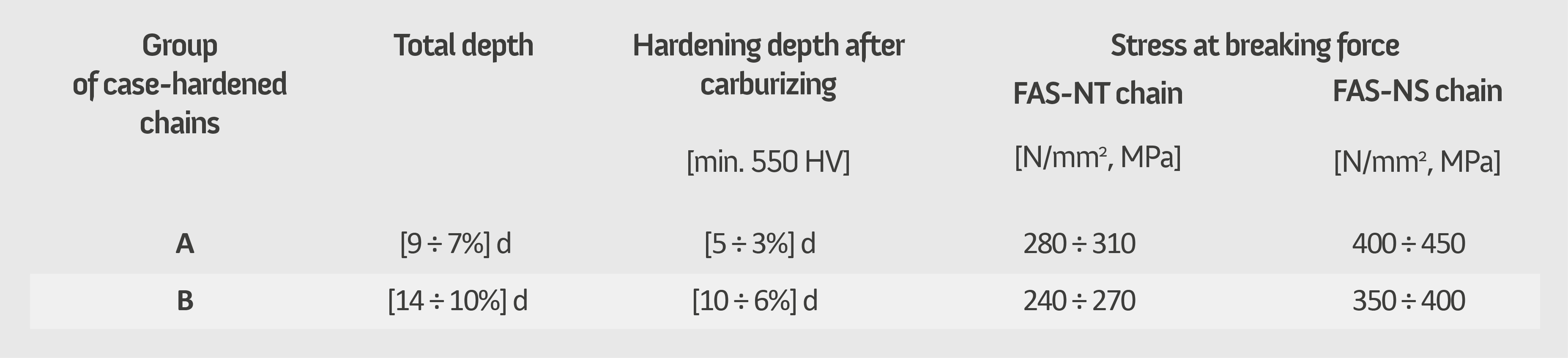

Mechanical properties

Mechanical properties of case hardened chains depend on the carburizing depth. The depth can reach up to max. 14% of pin diameter. The deeper the carburizing the smaller breaking force is observed. The unit elongation at breaking force is only 1,5 ÷ 3%.

Depending on carburizing depth, the chains are manufactured in two group types:

group A

total carburizing depth within the range:

(9 ÷ 7%) d (0,09 ÷ 0,07) × d

group B

total carburizing depth within the range:

(14 ÷ 10%) d (0,14 ÷ 0,10) × d (d - chain diameter)

Surface hardness of case-hardened chains is ca. 800 HV (740 HBW, 63 HRC). Hardness of the core (beyond the carburizing level) in FAS-NS chains is min. 400 HV (380 HBW; 40,8 HRC) – 5% decrease in hardness is acceptable – its value is two times higher than the core hardness of FAS-NT chains, which is min. 200 HV (190 HBW) – 5% decrease in hardness is acceptable.

! Due to production technology, the case-hardened chains are hard and brittle. An equipment designer should take into account the maximum (the highest possible) safety factor value for working load limit (WLL) in the kinematic and dynamic system. Improper use of chain (exceeding WLL) may cause chain failure in a brittle manner with link falling into small pieces. Their significant force may jeopardize the safety and health of workers who are in the immediate vicinity of chain operation area.

Case-hardened chains can be loaded only with a force that is longitudinal to chain axis. It is unacceptable to:

• weld any elements to chain links,

• load the chain links with lateral force that spreads the link from the inside or load them with compressive force that acts from the outside,

• load the chain links with impact forces, strokes.

Stress at breaking force based on carburizing depth

Dimensions and mechanical properties